Fire/rescue apparatus represents the backbone of emergency response efforts, crucial for combating fires and ensuring public safety. Understanding these specialized vehicles and their functionalities helps illuminate their significance in community protection and disaster management. Each chapter in this exploration will dissect the components and unique features of fire/rescue apparatus, their applications in emergency response protocols, and notable technological advancements, all of which enhance the efficiency and effectiveness of firefighting and rescue operations.

Anatomy in Motion: How a Fire/Rescue Apparatus Turns Training into Life-Saving Action

A fire/rescue apparatus is more than metal and paint; it is a moving embodiment of training, judgment, and collective response. When an alarm sounds, it becomes a compact command post, a mobile workshop, and a heavily armored lifeline all at once. To appreciate what it does, one must move beyond the gleam of the cab and the shine of the sirens and consider the way its components converse with each other under pressure. What sets these machines apart is not a single feature but the seamless orchestration of many parts, designed to anticipate the unpredictable realities of a crisis and to adapt as the situation evolves. In this sense, a fire/rescue apparatus is a deliberately engineered ecosystem that translates decades of field experience into a retrievable, deployable, and relentlessly reliable tool for saving lives and protecting property.

At the heart of every apparatus lies the pump system, a disciplined system of hydraulics and power delivery that makes water behave as a controllable force rather than a mere resource. The pump draws water from hydrants when streets are crowded with traffic and valves the size of a person’s leg stand at attention to regulate the flow. In more challenging terrains or during wildfire operations, the pump can draft from natural water sources—ponds, streams, even small bodies of standing water—via suction hoses and carefully managed strainer intakes. Modern pump configurations are often multi-stage, a design that allows responders to switch rapidly between high-volume supply and precise, high-pressure application. The ability to shift pressure and flow with minimal delay is not a luxury; it is a necessity when a firefighter needs to coax a torrent of water through tangled streets or through the narrow cones of a building’s interior. The pump’s performance has a cascading effect on every other subsystem: a robust supply strengthens the ladder team’s reach, and a reliable pressure helps the frontline crew maneuver complex nozzles and monitors with confidence. In practice, the pump is both a technical head and a tactical instrument; its capabilities define what is possible on the ground and shape the tactical choices that accompany every call.

The water tank is the other side of the same coin. While the pump might pull from outside sources, the onboard tank guarantees an immediate, drinkable, and storable quantity of water. This onboard reserve ensures responders begin work immediately, even when hydrants are distant, blocked, or unusable. The tank’s size is a function of the vehicle’s design, jurisdictional policy, and anticipated response needs. A larger tank—common in engines built for urban response—provides a protective buffer while crews establish a reliable external water supply. A smaller tank might favor quicker acceleration and increased maneuverability in tight streets. In every case, the tank anchors the apparatus in the moment of initial deployment, buying time for more complex water strategies to come online. Yet the presence of onboard water is more than practical; it influences posture. Firefighters can commence luminal ventilation, perform initial rescue work, and establish an initial water curtain before external water supply is secured. The tank, in effect, roots the apparatus in the present while the rest of the system moves toward the future.

Ladder and aerial apparatus constitute the visible reach of the fire/rescue machine. When the call demands elevated access, the extendable ladder becomes a bridge between the ground and the upper floors, a mechanical lifeline for rescue, and a dynamic platform for directing water from above. Modern ladders or aerial devices are not just long arms; they carry water cannons—monitors—that allow firefighters to project streams of water across vertical distances with precision. The ladder also functions as a ventilation tool, a way to clear heat and smoke from enclosed spaces, thereby improving conditions for victims and responders alike. In many scenarios, the ladder’s position affects the outcome of a rescue: the angle of approach, the height reached, and the ability to work from a stable, supported perch all influence the speed and safety of the operation. The technicians who operate these devices train extensively to synchronize movement of the ladder with the crew’s tasks on the ground, ensuring that the aerial platform complements the engine’s water supply, the rescuer’s tool use, and the medical triage process, all in a single, coherent maneuver.

Rescue equipment sits at the core of the apparatus’s life-saving mission. Hydraulic cutters, spreaders, and rams are the classic quartet of extrication tools that enable responders to pry open metal, create escape routes, and liberate victims trapped in vehicles or embedded in collapsed structures. The specificity of each tool matters. Spreaders work to push and pull through tight spaces, while cutters slice through metal with a controlled, measured bite. Rams provide leverage to widen gaps or create necessary room for patient access. But the tools themselves are not used in isolation; their effectiveness emerges only when operators coordinate them with the pump’s water supply, the ladder’s reach, the protective gear, and the crew’s medical priorities. The extrication operation becomes a choreography: stabilize the vehicle, assess the patient’s condition, create a safe access path, and then execute the rescue while ensuring that cut surfaces and beams do not endanger occupants or responders. The careful handling of each tool—its placement, timing, and sequence—speaks to a philosophy that prioritizes speed without sacrificing safety.

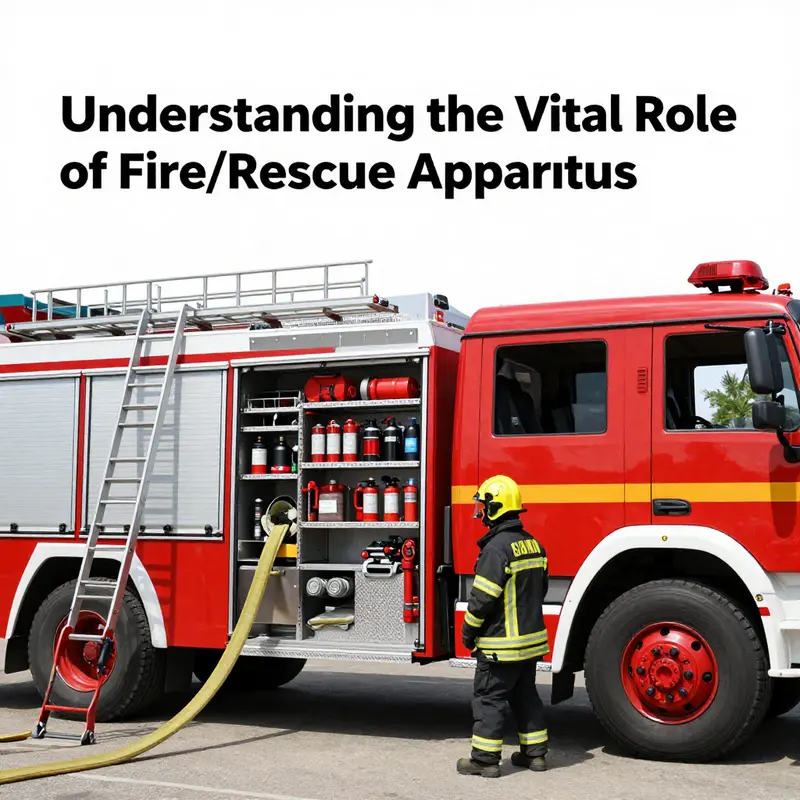

Beyond the behemoths of suction and leverage lies the quiet architecture of storage and organization. Specialized compartments and storage systems are not decorative; they are the strategic nervous system of the apparatus. They hold protective gear, medical supplies, spare nozzles, hoses, adapters, and a host of small devices that can dramatically alter response times. These compartments must balance accessibility with protection, ensuring sensitive equipment remains secure while the vehicle is maneuvering through traffic, scanning for hazards, or waiting for a critical moment to respond. The way tools are arranged can determine whether a crew reaches a patient in seconds or minutes, and seconds matter in emergencies. The design of these storage systems reflects a deep understanding of the typical sequences in a call: water, access, rescue, and care. When a team opens a compartment, it must feel like a practiced hand entering a reliable tool cabinet, not a random scavenging exercise. This reliability reduces cognitive load on responders, allowing them to focus on patient care, hazard recognition, and communication with other units and the command center.

No finite piece of equipment operates in a vacuum; communications technologies knit the entire apparatus into a larger network. Modern response relies on real-time data exchange, not only within the crew but also between the apparatus, the incident commander, firefighters on the ground, EMS teams, and nearby units. Radios, intercoms, and data terminals create a shared situational awareness that makes it possible to adjust tactics as the scenario unfolds. A moment’s hesitation can cascade into miscommunication; thus, the clarity, redundancy, and reliability of the communication system are as vital as any mechanical component. In practice, this means more than voice contact. It means the ability to transmit ongoing status updates, pump pressures, patient counts, and hazard identifications in a way that reduces ambiguity and speeds decision-making. The design philosophy thus treats the apparatus as a mobile node in a network, a node that must stay connected even as it moves through urban canyons, rural roads, or crowded highways.

Onboard lighting and sirens complete the triad of visibility, signaling, and safety. Adequate lighting is essential when crews arrive at night or in smoke-filled environments. It reveals the interior layout of a burning structure, highlights obstacles, and helps guide a victim toward safety. Sirens and warning lights are not mere theatrics; they are critical life-safety tools that facilitate rapid, predictable movement through traffic and alert bystanders to the presence of responders. These systems must be resilient enough to function in austere conditions, where water spray, heat, and motion could compromise sensitive electronics. The choreography of lights, sounds, and work surfaces becomes part of the incident’s tempo; it communicates urgency to bystanders while signaling to on-scene personnel the status and position of the apparatus itself.

The human factor threads through every subsystem. Driver training and vehicle maintenance are not afterthoughts but essential practices that determine whether the apparatus can perform when it is most needed. The operator must navigate congested streets, obey traffic laws, and maintain situational awareness while coordinating with a team that is deploying pumps, ladders, and rescue tools. Regular maintenance—inspections of pumps, hydraulics, ladders, electrical systems, and hose lines—ensures that all components respond as expected in moments of strain. The failure of a single subsystem can create cascading risk for rescuers and civilians alike, turning a controlled situation into a chaotic one. Consequently, maintenance and training are not discrete tasks but ongoing disciplines that keep the equipment reliable, predictable, and ready for deployment at a moment’s notice.

As the apparatus moves from the scene to the stand-by point, its design philosophy reveals a deliberate balance between robustness and adaptability. A fire/rescue vehicle must be sturdy enough to weather the impacts of road handling and the harsh conditions of a structure fire, yet agile enough to operate in narrow streets, crowded venues, or uneven terrain. The modular nature of these vehicles supports diverse mission profiles. Some units emphasize rapid water deployment and extended reach, while others hinge on comprehensive rescue capabilities and advanced medical support. The exact combination depends on learnings drawn from a century of operations, but the underlying principle remains constant: the apparatus is a holistic instrument that harmonizes power, reach, tools, communication, and human skill. Its value lies not in any single feature but in the confidence it gives responders as they approach a crisis, knowing they have a well-coordinated system behind them.

Historically, the evolution of fire/rescue apparatus mirrors the evolution of firefighting itself. Each generation of vehicle integrates exploratory advances in hydraulics, materials science, ergonomic design, and on-board technology. The result is a machine that can bend to the demands of a particular incident while maintaining universal capabilities that allow it to function in many different scenarios. The most effective apparatuses are not static; they carry within them the possibility of future improvements—the capacity to add new tools, adjust compartments, or reprogram a communications interface as new threats emerge and as the body of practice grows. In this sense, the apparatus is both a product and a platform: it embodies current expertise while offering a framework for ongoing enhancement.

To appreciate the broader arc of these machines, consider how the field has increasingly integrated experiences from research, drills, and real-world incidents into design thinking. This convergence is visible in thoughtful documentation, training programs, and exhibitions that reflect on how technology, strategy, and human judgment intersect in life-saving work. For readers who want a glimpse into this ongoing conversation about practice and innovation, certain institutions and displays emphasize how fire services adapt with new knowledge and tools. A resource that captures this spirit is the Innovation Museum Transforming Fire Services, which explores how lessons learned on the front line translate into design and policy improvements for future responders. See the discussion here: Innovation Museum Transforming Fire Services. This kind of synthesis—between field reality, design thinking, and public understanding—helps illuminate why the apparatus looks the way it does and why it behaves the way it behaves under stress.

The final piece of the puzzle is the broader ecosystem in which the apparatus operates. Fire/rescue departments are, in effect, networks of people, training, equipment, and governance. The apparatus connects to this network through its communications systems, medical kits, and the shared protocols that standardize how teams respond to an emergency. The NFPA plays a central role in shaping these standards, providing guidelines that inform pump capacities, hose loads, ladder outreach, vehicle safety, and maintenance programs. The official NFPA resources, which detail the technical specifications and performance benchmarks for fire apparatus, offer a comprehensive baseline for how departments plan, purchase, and operate these essential tools. For those seeking more precise, technical information about types and specifications, see the Global standards and practices resources provided by the NFPA at https://www.nfpa.org/.

In sum, a fire/rescue apparatus is a carefully engineered combination of water management, reach, rescue capability, organization, communication, visibility, and human skill. Its strength lies not in any one system but in the disciplined integration of many—an integration that turns a vehicle into a lifesaving instrument. The next time a team rolls toward a blaze, a high-angle rescue, or a vehicle crash, the audience should see more than a vehicle; they should sense a deliberate, practiced coordination that translates training into action, risk into control, and uncertainty into life-preserving possibility. The apparatus is, in short, an embodiment of preparedness in motion, a mobile embodiment of the principle that when seconds count, a well-made tool can make the difference between tragedy and survival.

Armament for Alarm: How Fire/Rescue Apparatus Are Built to Fight Fires and Rescue Lives

A fire/rescue apparatus is more than a vehicle with a hose. It is a mobile workshop, a lifelike extension of a fire station, and a carefully engineered response system designed to meet the unpredictable rhythms of an emergency. When a call comes in, every component of the apparatus moves in concert—from the engine’s power to the last tool in the compartment. The result is a multifunctional platform that can begin suppression, lend a hand in a dangerous space, and stabilize a scene while additional resources arrive. This chapter traces the spectrum of these machines, not as a catalog of parts, but as a narrative of how people, design, and technology converge to address the very human needs at the heart of emergencies. The discussion unfolds in a way that honors the breadth of scenarios responders face—from the distant glow of a wildfire to the precise choreography of a high-rise rescue, and from hazardous material spills to structural collapses. Each scenario shapes the architecture of the apparatus and, in turn, the capabilities available to firefighters and rescue workers at the moment of truth.

Wildland fire response devices anchor the early, often uneven, battles waged against nature’s more unpredictable flames. Wildland fire engines are built for off-road mobility, with higher ground clearance and four-wheel drive that can kiss the edge of a forest road or punch through a dense brush line. They carry larger water tanks, typically in the range of five hundred to a thousand gallons, to reach remote flames where hydrants do not exist. A critical component in these environments is the dry chemical system, which can rapidly suppress fast-moving grass and brush fires where water alone would take too long to deploy. The smaller yet rugged brush trucks complement these capabilities with nimble handling and a focus on tight spaces in rugged terrain. Their equipment emphasizes rapid suppression in spots where a larger engine cannot reach, and they are often configured to deliver foam or water in a compact form that can be maneuvered quickly through uneven ground. A separate but equally vital asset in remote suppression is the water tender, conceived not to fight on the fireline directly but to ferry large volumes of water to refilling points so that smaller units can stay engaged without returning to a distant water source. The water tender, with its large tank and robust pump, becomes the hydrogen that keeps the field operation moving, enabling the frontline engines to stay in the fight longer and farther from built infrastructure.

Urban settings demand a different balance of power, reach, and exactitude. Pumper trucks, the workhorses of city firefighting, are designed to deliver high-pressure water efficiently. They typically mount powerful pumps that can push water at several thousand gallons per minute, which translates into a broad array of hose layouts and rapid deployment of streams across multiple positions. The water tanks in these vehicles often range from five hundred to a thousand gallons, allowing sustained attack without constant water supply concerns. Foam systems add a layer of versatility, enabling suppression of mixed fuels or complex flame scenarios where water alone would be insufficient. Then there are ladder trucks, or aerial platforms, whose raison d’être is access—reaching upper floors and enabling rescue from heights that would otherwise trap occupants or complicate the fire’s progression. The ladders themselves extend to substantial lengths, commonly between seventy-five and one hundred feet, and include an onboard water cannon to begin interior cooling and exterior exposure protection from a safe distance. The combination of high-pressure delivery and elevated reach makes these apparatus indispensable to urban defense, where buildings and street networks create unique challenges and opportunities for firefighters.

Beyond the lines of flame and smoke lies a more specialized dimension of emergencies: technical rescue apparatus. These vehicles do not fight fire in the traditional sense but instead carry a suite of tools designed to extricate, stabilize, and preserve life when accidents create complex, constrained environments. The core toolkit typically includes hydraulic cutting tools and spreaders, used to pry open crushed frames and widen spaces for access. Saw blades and high-pressure airbags enable controlled lifting and debris movement in confined spaces, while winches and towing lines provide the anchor points necessary to manage heavy loads and prevent further collapse. Technical rescue units are configured to carry an expansive array of tools that can be rapidly deployed in a scene where time, space, and safety converge. The emphasis here is on precision, control, and the ability to adapt the equipment layout to a changing scenario. In essence, these vehicles embody a philosophy of modular readiness: they start with a baseline set of capabilities and can be expanded with additional tools as the incident dictates, without sacrificing mobility or speed.

Hazardous materials response units add another layer of capability, oriented toward containment, decontamination, and protective measures in the face of dangerous chemical, biological, radiological, or toxic releases. A HazMat apparatus is outfitted with protective gear and decontamination systems designed to shield responders and to manage exposure in the field. The vehicles carry equipment for monitoring and identifying hazardous substances, as well as containment tools to isolate a spill and prevent spread to uncontaminated areas. Sealed compartments help safeguard sensitive materials and maintain integrity in potentially corrosive environments. The approach here combines engineering with stewardship: compartments and systems are designed not only to endure the risks posed by hazardous materials but also to minimize the chances that responders will carry contaminants from one location to another. The overarching aim is to keep the responders safe while enabling them to stabilize the incident at its source and coordinate with hospitals, public health authorities, and environmental agencies to ensure a comprehensive response.

The thread that ties all these different apparatus together is a modern reverence for technology as a force multiplier. Global firefighting and rescue operations increasingly rely on real-time information and precision communication. GPS tracking and real-time navigation help the incident commander allocate resources and track deployment across a sprawling scene. Onboard communication systems coordinate crews, monitor changing conditions, and synchronize actions with incoming units. Real-time diagnostic tools monitor engine health, pump performance, and critical systems, enabling preemptive maintenance and faster recovery from hiccups that could otherwise delay response. This technological integration does not replace the craft of firefighting and rescue work; it amplifies it, granting responders the situational awareness and operational tempo needed to meet evolving hazards. The aim is not to replace human skill but to extend it in ways that reduce risk, increase effectiveness, and accelerate the transition from initial alert to final scene stabilization.

Despite these broad categories, the design of a fire/rescue apparatus remains deeply contextual. The terrain, climate, population density, and types of threats that a department faces shape the equipment mix. A region with a dense urban core and aging infrastructure may prioritize high-rise access and rapid foam-capable pumps, while a rural district with long response times and water-scarce conditions may lean toward larger water tanks, off-road traction, and efficient water shuttle capabilities. In many places, these needs converge, prompting creative, tailored solutions that blend mobility with capacity. A recent trend in this direction is the exploration of comprehensive configurations that align with local risks while remaining adaptable to a wide range of contingencies. These hybrid approaches aim to deliver a cohesive toolkit—where a single platform can be reassigned or reconfigured to address different emergencies without sacrificing reliability or speed. It is this kind of adaptive thinking that elevates the concept of a fire/rescue apparatus from a mere vehicle to a strategic asset in public safety. See how one approach emphasizes comprehensive, adaptable fleets for developing countries, reflecting a broader push toward versatile, scalable solutions that can meet diverse firefighting and rescue needs: Comprehensive custom fire trucks for developing countries—advanced solutions for diverse firefighting needs.

As communities grow and hazards evolve, the interplay between design and operation becomes even more critical. A well-prepared department does not rely on a single type of apparatus to confront all risks; instead, it builds a balanced portfolio that can be deployed in a stepped sequence. Early stages of an incident might rely on rapid initial attack from a pumper, supported by a ladder company that can secure upper access while crews deploy portable lighting and ventilation equipment. If the scene evolves into a rescue scenario, the technical rescue unit can transition the operation toward stabilization and extrication, while HazMat teams address any chemical risk. This sequencing—assessed and guided by the incident commander in real time—underscores the value of interoperability. The vehicles themselves are scaled to shrink the distance between the moment the alarm sounds and the moment rescue begins. They are designed to be quickly maneuvered, quickly armed with the right tools, and quickly integrated into a broader strategy that includes EMS, public safety communications, and, when necessary, disaster response coordination.

The latest iterations of fire/rescue apparatus also reflect a growing sensitivity to the realities of training, maintenance, and lifecycle costs. Mobility and capability alone do not determine value; reliability and ease of maintenance do. Designers incorporate modular compartments, standardized mounting points, and common spare parts to extend the life of these platforms and to simplify upgrades as new sub-systems become available. This approach helps departments manage budgets while maintaining a high level of preparedness. It also reduces downtime, enabling responders to return to service sooner after wear, damage, or routine maintenance. In practice, the most effective fleets blend rugged reliability with modularity. They are built to endure the harsh realities of daily duty and yet flexible enough to accept new tools, sensors, or safety features as science and practice advance. The result is not merely a collection of machines, but an ecosystem of response, each element reinforcing the others, and each vehicle carrying with it a promise that when a call comes, the answer will be ready.

In sum, understanding the types of fire/rescue apparatus and their unique features is more than a taxonomy. It is an invitation to see how a community translates risk into capability. The wildland engine, the urban pumper, the aerial ladder, the technical rescue unit, and the hazmat platform—all are guided by a shared goal: to arrive fast, work safely, and restore order with minimal harm. The modern apparatus exists at the intersection of tradition and innovation, where disciplined practice meets high-tech reliability. It is the product of years of field experience, careful engineering, and the stubborn insistence that emergencies demand both courage and competence. As risks evolve, so too will the equipment that translates human intention into lifesaving action. The chapter you have read is but a map of this expanding field, inviting ongoing learning and thoughtful investment in the tools that keep communities safe when seconds count, and when the landscape of danger is as diverse as the people it serves.

External resource: Guidelines for Safety in Wildfire Suppression Operations (YJ/T 35-2025). https://www.mem.gov.cn/gkml/xfj/202601/t20260116_498725.html

Mobilizing Safety: The Fire/Rescue Apparatus as the Pulsing Core of Emergency Response

When the alarm sounds, the fire rescue apparatus moves from transport to a focused instrument. It is a mobile command center, a workspace on wheels, and a platform for life saving actions. The arc of an incident centers on the vehicle and its integrated system, including propulsion, water delivery, rescue tools, medical readiness, plus communication, command, and training. This integration makes it a critical node in a data driven, protocol guided ecosystem.

The heart of the apparatus is the ability to deliver water under pressure where it is needed most. The fire pump converts stored energy into high pressure flow that travels through hoses to suppress flames, protect exposures, and create a safe working environment for crews. In urban settings a pump must deliver hundreds to thousands of gallons per minute while maintaining steady pressure as firefighters manipulate nozzles, lay large diameter lines, and coordinate actions at the scene. When hydrants are not available the ability to draft from natural sources becomes essential. A robust pump system with redundancy and protection against cavitation and seal wear ensures water moves when it is most critical, reducing delays and enabling teams to establish attack lines before the fire advances. The onboard tanks provide initial volume to accelerate suppression and buy time during the critical window.

Hoses are the lifelines of the operation, but their true value emerges when crews deploy them with discipline. Beyond their diameter and length, the way hoses are handled, including coiling, advancing, and maintaining pressure, significantly affects reach and control while reducing line failure under dynamic conditions. The hose complement reflects the mission mix of the department, with larger layouts for high rise fires and complex exposures, shorter lengths for close quarters, and pre connects designed for rapid attack. The accompanying tools—valves, adapters, nozzles, and flow control devices—allow crews to tailor the water stream to the fire geometry, cooling hot gases and creating safer paths for interior movement. The pump, tank, and hose form a coordinated system; when one part underperforms the response suffers, but when they work together the water can be introduced quickly and precisely.

But a fire rescue apparatus does not exist only for extinguishment. Modern responses hinge on rapid access to victims, stabilization of scenes, and extraction of people from trapped situations. The rescue capability, including hydraulic rescue tools, is paired with rope systems, rigging, and stabilization gear that allow responders to reach, lift, and maneuver with precision. The emphasis is on preserving life and reducing further harm, coordinating cutting, spreading, prying, and lifting with patient care and scene safety. The apparatus provides the necessary speed and force while maintaining a safety margin for both victims and rescuers. In this sense the vehicle becomes a platform on which rescue protocols are enacted and adjusted in real time.

The modern engine of the apparatus also encompasses medical readiness. Some responses require immediate on scene stabilization and triage, and several apparatus are designed to function as mobile emergency care units. They carry essential medical equipment, protective gear, and consumables to administer life saving interventions while the scene is secured and before transport. This EMS capability reduces treatment delays and helps stabilize patients during the critical window before hospital care. The presence of medical resources on the apparatus also supports disaster response by enabling a unified and scalable approach to triage, treatment, and transfer decisions in mass casualty events. Practically this means a single vehicle can deliver water, maintain a stable scene, and provide on site medical care, which streamlines coordination under pressure and reduces overall risk.

This triad of functions rests on disciplined operations and ongoing training. The success of a live response hinges on maintenance, condition monitoring, and reliable performance of every system on board. Pumps must be primed and primed correctly, all seals must be intact, hoses free of damage, extrication tools operating smoothly, and medical equipment checked. A failure in any area can lead to delays and higher risk for responders. To mitigate these risks fire departments implement comprehensive training programs that emphasize not only technical proficiency but also communication, teamwork, and decision making under stress. Drills simulate real world complexities, from multi agency coordination to evolving hazard scenarios, ensuring crews adapt to changing conditions and maintain a clear unified command structure at the scene. The importance of pre deployment checks cannot be overstated. A routine that covers every system from water pumps to SCBA cylinders reduces chances of failures under pressure and strengthens overall readiness.

The apparatus also functions as a node of information and command in an incident command system. On arrival crews assume roles, establish communication lines, and begin integrating with other responders, law enforcement, and public safety agencies. The vehicle presence signals that responders are prepared to marshal manpower, equipment, and resources in a coordinated fashion regardless of incident scale. This is critical in urban environments where access, traffic, and building density complicate operations. In rural or wildland settings the same vehicle may serve as a mobile shelter, a fuel resupply point, or a staging area for longer term operations. The design must consider terrain adaptability, weather resilience, and versatility in equipment configuration. The command function is embedded in how the apparatus is equipped, organized, and supported by the crew, who are trained to shift from tactical to strategic thinking as the incident consolidates.

Design decisions reflect a balance between readiness, cost, and longevity. Equipment on board should be robust against corrosion, capable of withstanding years of exposure to heat, water, and mechanical stress, and flexible enough to accommodate new tools and technologies. The tradeoff between durability and weight is a constant challenge. Heavier rigs deliver more in terms of water and power but can slow response in congested or rough terrain. Departments address this tension by tailoring vehicle class to common scenarios and adopting modular configurations that can be swapped or upgraded as needs change. It is a pragmatic approach grounded in data, risk assessment, and real world experience, underscoring that there is no one size fits all solution when the mission spans kitchens fires to collapsed structures or swift water rescues.

In settings with limited resources the challenge grows more complex. The literature on developing country contexts highlights the value of adaptable, cost effective firefighting solutions. The emphasis shifts from possessing a single all singing all dancing apparatus to ensuring a fleet of vehicles that can be deployed quickly, maintained easily, and supported by reliable supply chains. A thoughtfully designed fleet prioritizes core capabilities—water delivery, rescue access, and basic medical readiness—while enabling targeted augmentations for specialized tasks. In such contexts the strategy often centers on local capacity building, affordable maintenance programs, and partnerships that extend the life and effectiveness of each vehicle. These considerations are not concessions to limitation; they are disciplined acknowledgments that reliability and speed of response hinge on tools that are accessible, understandable, and durable under local conditions. The goal is a resilient, scalable backbone for emergency services that can adapt as communities grow and hazards shift.

The broader significance of the fire rescue apparatus extends beyond the immediate incident response. Its presence at a scene transforms it from an isolated event into a coordinated public safety operation that engages hospitals, public health agencies, and community education efforts. Fire apparatus contribute to public awareness campaigns, structural safety programs, and disaster preparedness planning. They are symbols of readiness, capable of delivering not just water or rescue services but also a sense of security to a frightened populace. This is more than a logistical achievement; it is a social one. When communities observe a well equipped, well trained response system, trust in public safety deepens, and preventive measures gain traction. The apparatus therefore embodies a national or regional commitment to safety, illustrating how investments in equipment, training, and systems translate into tangible life saving outcomes.

The chain of readiness extends to maintenance and readiness as well. Agencies recognize that keeping a fleet ready requires ongoing investment in inspection programs, parts inventories, and technician training. Routine checks for pump performance, seal integrity, priming efficiency, and hose condition prevent failures during critical moments. Training programs that simulate real time decision making reinforce the human element—how crews communicate, how they assign tasks, and how they adapt when a scene evolves. The maintenance culture complements the technical design, ensuring that the hardware and the people who use it remain in a perpetual state of readiness. In this sense the apparatus is not only a tool for managing fire and rescue operations but also a catalyst for professional development, interagency cooperation, and continuous improvement across the emergency response ecosystem.

The interconnection of technology, training, and policy is evident in the way emergency response protocols are written and practiced. Local national and international guidelines shape every facet of the apparatus from pre deployment checks and real time communications to the sequence of actions that responders take upon arrival and during the stabilization phase. The enduring lesson is that the vehicle value is amplified when it operates within a well conceived framework that supports rapid decision making, clear roles, and a shared mental model among diverse teams. That framework in turn is reinforced by ongoing research, standards, and field drills that push responders to refine their skills and align their practices with best available evidence. In short, the fire rescue apparatus is a living instrument of safety a vehicle that holds the potential to transform a chaotic scene into a controlled life affirming response.

For readers seeking to trace the practical implications of these ideas the broader conversation about apparatus design and deployment is reflected in a growing body of literature and case studies. One particularly relevant thread highlights how comprehensive customized fire truck solutions can address diverse rescue needs without sacrificing reliability or maintainability. This thread underscores the idea that developing resilient public safety fleets requires thoughtful design sustainable support and a shared commitment to service delivery that puts human life at the center. To explore a concrete example of these principles in action consider the following internal resource: comprehensive customized fire trucks for developing countries. This resource illustrates how modular configurations cost conscious engineering and strong aftercare arrangements can yield a fleet capable of meeting varied emergencies while remaining sustainable over time. It is a reminder that the assertion of readiness rests on more than hardware it rests on the people who operate it and the systems that keep it ready to serve.

As the discussion closes on the role of the fire rescue apparatus it is clear that the vehicles value is measured not only by the number of incidents it helps resolve but by the resilience it contributes to the communities it serves. The apparatus embodies the synthesis of engineering excellence human expertise and organizational discipline. It enables departments to fulfill their multifaceted missions fire suppression rescue hazardous materials response EMS and disaster coordination while remaining adaptable to future challenges. Selecting maintaining and training around the right apparatus thus becomes a central continuing priority for public safety infrastructure. It is not a standalone investment but a dynamic commitment to preparedness safety and community trust. In the end a fire rescue apparatus is more than steel and hoses it is a symbol of readiness a catalyst for effective action and a lifeline that intersects with every layer of emergency response to create a safer more resilient society for practitioners and planners alike its study remains essential guiding decisions that affect outcomes at every stage of an incident and long after the last flame is extinguished.

Bold Giants on the City Streets: The Evolution and Technological Odyssey of American Fire/Rescue Apparatus

The fire and rescue apparatus that now roars down American avenues is more than a tool; it is a living statement about a city’s priorities, its history, and its capacity to adapt under pressure. In the span of a single century, the American fire engine grew from a handful of horse-drawn rigs to a fleet of purpose-built machines that blend brute power with fragile finesse. The city’s neighborhoods, with their steep streets, soaring high-rises, and crowded blocks, did more than shape these vehicles; they demanded them. The resulting machinery carries a badge of local identity, a color scheme that identifies a department from a distance, and a practical philosophy about readiness that is constantly tested by the unpredictable theater of urban emergencies. This combination of cultural pride and technical necessity makes the American fire apparatus a unique artifact in the broader history of public safety equipment. It is not merely about putting out fires; it is about delivering aid, stabilizing chaos, and signaling to residents that help will arrive with speed, authority, and a degree of spectacle designed to reassure as much as to deter danger.

The evolution of these vehicles has always been tethered to the needs of the engine room and the street above it. In the early days, firefighting was a process of manual labor, improvisation, and shared risk. As municipalities consolidated and budgets expanded, the apparatuses became larger and more specialized. Today, you can distinguish an engine from a ladder truck not only by the silhouette but by the spectrum of capabilities they carry. Engines are the pumping heart of a response, capable of delivering thousands of gallons of water per minute through large-diameter hose lines to suppress flames rapidly. Ladder trucks, with their soaring aerial platforms, provide elevated access and ventilation, enabling firefighters to reach upper-story hazards and rescue occupants trapped above ground level. Pumper trucks combine the best of both worlds, delivering pressure and mobility on routes where water supply is precarious or inconsistent. And beyond these core types, American fleets now include vertical-tampering units, technical rescue platforms, and mobile command vehicles that glue together tactics from fire suppression, EMS, and incident management. The result is a family of vehicles that looks almost like a city’s operating theater on wheels, each piece performing a specific act while contributing to a larger, coordinated performance.

One element that remains striking, even as technology accelerates, is how the American apparatus embodies a sense of identity. Departments have embraced bold color schemes, heraldic crests, and distinctive silhouettes, turning a fire truck into a moving billboard of community pride. This visual language does more than attract attention; it signals to residents and visiting crews a department’s history, its values, and its readiness to respond. This emphasis on visual identity diverges in notable ways from some European and Asian rivals, where designs often favor functional elegance and streamlined profiles over flamboyant display. The American emphasis on visibility and personality has practical consequences. Bright colors and high-contrast markings can aid in roadside safety, improve situational awareness on crowded streets, and reinforce public trust in the department’s presence. At the same time, this cultural expression can complicate procurement and maintenance, because the most dramatic aesthetic features must be maintained alongside the heavy demands of daily service. Still, the trade-off is generally accepted because it preserves the public-facing ethos that undergirds the firefighting mission.

The modern apparatus must do more than carry water and raise ladders. It has become a platform for an ever-expanding set of tools and capabilities, a mobile workshop that can be deployed to a broad spectrum of emergencies. Pumps have grown smarter, with variable-speed drives, integrated relief valves, and advanced hydraulic systems that optimize pressure with minimal energy waste. The fuel systems—once a straightforward matter of range and endurance—now intersect with telemetry, allowing fleet managers to monitor fuel consumption, engine temperature, and valve positions in real time. This real-time visibility is not a luxury; it is a prerequisite for reliability in situations where minutes matter and equipment failures can have life-or-death consequences. And with a global push toward sustainability, many new chassis and powertrains are lighter, more durable, and more fuel-efficient than their predecessors, even when carrying heavier payloads. The result is a curious paradox: the vehicles have grown more powerful and technologically sophisticated, yet they also become more attuned to the needs of the planet they inhabit.

At the heart of this technological ascent lies a suite of sensing and information systems that extend beyond the pump, ladder, and pump operator’s hands. Thermal imaging cameras, once a specialized add-on, are now integrated across new platforms, helping crews locate hot zones behind walls, identify occupants in smoke-filled rooms, and map heat signatures that inform ventilation and suppression strategies. Global Positioning System (GPS) navigation, digital mapping, and integrated communications unify the crew’s movements with dispatcher screens, incident command centers, and arriving units. Modern apparatuses often include dedicated on-board computers that collect data from dozens of sensors—pressure gauges, flow meters, hydraulic temperatures, and battery health—configuring an operating picture that supports both immediate decision-making and long-term maintenance planning. This data-rich environment allows departments to monitor performance, predict failures before they occur, and optimize deployment patterns so that responses arrive not only faster but smarter.

The integration of data analytics into routine operations has transformed preventive maintenance from a quarterly ritual into an ongoing, data-driven discipline. Telematics systems track miles traveled, vibration patterns, fluid levels, and component wear, generating maintenance timetables that can be adjusted in real time based on actual usage. The days of scheduled, calendar-based servicing are giving way to condition-based maintenance, where the health of every subsystem—pump, drivetrain, braking, electrical networks, and hydraulic circuits—dictates when service is due. This approach reduces downtime, extends equipment life, and ensures that when a call comes in, a rig is as ready as it can be. The emphasis on reliability has helped shift the public narrative from one of heroic improvisation to professional, predictable performance. It is not that risk disappears; it is that risk is managed through a relentless, instrumented focus on readiness.

Another dimension of this evolution is the shift from a purely firefighting apparatus to a multi-functional platform. Modern crews rely on a single vehicle to perform roles that once required several specialized units. The high-rise environment, for example, has reframed what a ladder truck must accomplish: access and rescue in stairwells, egress for occupants, extraction of victims from confined spaces, and deployment of cutting-edge ventilation tactics. Hazmat incidents require sensors and containment tools that enable rapid assessment and isolation of dangerous substances. Vehicle extrication, once the specialty of a separate unit, is now a core competency embedded in many rescue platforms, with hydraulic cutters, spreaders, and stabilization equipment stowed alongside first-aid supplies and medical kits. In this sense, the apparatus has become a moving incident command post in its own right, a hub through which information, people, and materials converge toward a common objective.

This multifunctional character is not merely a technical convenience. It aligns with the realities of urban and suburban landscapes where proximity and density complicate response. The growing complexity of built environments—tall residential towers, sprawling shopping corridors, energy-intensive industrial sites—requires mobility, speed, and adaptability. A single, well-equipped platform can stage operations, command a scene, and serve as a lifeline for victims while other units are en route. The design implications are profound: the interior layouts must accommodate medical stations, space for technical tools, weatherproof compartments, and secure storage for sensitive equipment. Exterior engineering must support rapid, safe deployment under variable conditions, from icy streets to heat-scorched pavement. And because the urban public expects not only speed but also coordination, these vehicles increasingly function as a nerve center for the entire response network, synchronizing radio chatter, map updates, and resource allocation in a seamless, almost symphonic cadence.

The cultural dimension of American apparatus design also intersects with training and professional development. Firefighters are not merely operators of equipment; they are stewards of a highly specialized technology ecosystem. Training programs emphasize not only how to drive and deploy hoses but also how to interpret data streams, manage a fleet’s maintenance needs, and operate in concert with other agencies. The shift toward integrated incident management requires crews to think systemically: how a single intake valve affects water pressure downstream, how a thermal image readout informs a ventilation decision, or how a mobile command post can stabilize a chaotic scene long enough for additional units to arrive. In this sense, the apparatus becomes a teacher and a teammate, shaping the cognitive load of responders and sharpening their ability to execute complex plans under extreme pressure.

The aesthetic choices that define American apparatus also reflect practical lessons learned in the field. The bold, high-contrast markings improve visibility in smoke and at night, while the robust chassis and rugged finishes withstand the rough handling of urban streets, off-road terrains during wildland-urban interfaces, and the weather extremes of different climates. The strong, almost theater-like presence of these vehicles can be comforting to the communities they serve, signaling authority, readiness, and an enduring commitment to safety. Yet alongside that display, there is a quiet, technical undercurrent: frames crafted from advanced alloys, bodies sealed against corrosive chemicals, and matched powertrains engineered to deliver reliability even after thousands of service hours. The interplay of glamour and grit makes the American fire/rescue apparatus a compelling study in how public safety equipment can be both practically formidable and visually iconic.

Curiosity about how these machines evolve is not a vanity project; it is a practical question for departments that must balance immediate needs with long-range planning. Funding cycles, procurement rules, and the availability of skilled technicians all influence how quickly new capabilities appear on the street. The modern apparatus must be affordable to acquire, inexpensive to operate, and sufficiently flexible to adapt to future threats. This balancing act has spurred collaboration across disciplines, from mechanical engineering and materials science to human factors research and fire science. Departments increasingly seek partnerships that can deliver customizable solutions—systems that scale with a district’s risk profile, climate realities, and population growth—while maintaining a coherent, interoperable fleet that can operate alongside neighboring jurisdictions. In other words, the evolution is not simply about adding features; it is about building a resilient, adaptable architecture that communities can rely on for decades.

As these changes unfold, a thread of continuity remains: the apparatus is still deeply tied to human judgment and leadership. The driver who navigates congested streets, the officer who coordinates the scene from a portable console, the medic who switches to an EMS role without hesitation—all rely on equipment that behaves as an ally, not a liability. The promise of future innovations—autonomous support units, modular tool sets, even more advanced sensing networks—rests on this foundation of trust between people and the machines they depend on. The arc of the American fire/rescue apparatus is thus a story about partnership: between departments and communities, between engineers and end users, and between tradition and the relentless push of technology. It is a narrative that recognizes that courage in danger is complemented by a chassis, a pump, a ladder, and a data stream that work in concert to save lives.

For readers who want to explore how museums, demonstrations, and cross-disciplinary exhibitions illuminate this evolution, consider the innovations behind transforming fire services, which capture how technology, design, and human factors converge in practice. The ongoing dialogue between archiving, education, and frontline response helps explain why a modern rig looks and acts the way it does. This integration of culture, engineering, and emergency medicine is not an epilogue but a prologue to what comes next. The future will likely bring even tighter integration with smart city infrastructure, more sophisticated on-board analytics, and a broader array of mission profiles, from mass-casualty management to rapid deployment of medical surveillance during disasters. Yet the core impulse remains unchanged: to keep communities safe by delivering expertise, equipment, and reassurance exactly where and when they are needed most.

This evolving landscape invites ongoing curiosity about how far the form and function of fire/rescue apparatus can travel when guided by data, collaboration, and the stubborn pragmatism of those who serve on the front lines. It is a field where art and science meet in the heat and pressure of real emergencies, where a vehicle’s lines, colors, and gauges speak to a broader conversation about public safety, identity, and shared responsibility. The next chapters will continue to trace these trajectories, examining how new materials, smarter propulsion, and more integrated dispatch ecosystems reshape the daily realities of response. In the meantime, the image of the bold, capable machine rolling toward danger remains a potent symbol of communal resilience and the enduring human commitment to help one another in moments of peril. The journey is far from over, and it is precisely this sense of ongoing invention that keeps the story of fire/rescue apparatus both urgent and endlessly fascinating. Innovation Museum: Transforming Fire Services offers a thoughtful lens on how museums, demonstrations, and field practice converge to inform contemporary design and deployment.

For a more historical perspective on the American arc—from horse-drawn origins to modern powertrains—readers may consult external scholarship that captures the evolution in broader context. For more detailed historical context, see Fire & Rescue International’s feature on The Evolution of the American Fire Apparatus: https://www.fireandrescueinternational.com/features/the-evolution-of-the-american-fire-apparatus/.

Final thoughts

The fire/rescue apparatus stands as a critical asset in safeguarding communities and responding to emergencies effectively. By understanding its components, types, roles in protocols, and the evolution of technology, we can appreciate the professionals dedicated to preserving public safety. Ensuring that these specialized vehicles are well-equipped and maintained not only enhances their operational capacity but also reinforces community resilience against various emergencies.