Heavy rescue fire trucks play a pivotal role in emergency situations, responding to incidents that demand specialized equipment and expertise. These vehicles are crucial in saving lives during complex rescues, such as motor vehicle accidents or structural collapses. This article delves into the essential functions of heavy rescue fire trucks, highlighting their sophisticated equipment designed for intricate rescue scenarios. Each chapter will illuminate various aspects—from understanding the role these trucks play to the training required for teams that operate them, and finally, the broader impact of heavy rescue operations on community safety and emergency response efficacy.

Heavy Rescue on the Fire Truck: Tools, Teams, and Time-Sensitive Decisions that Save Lives

When a call arrives for people trapped after a crash, a collapsed structure, or a hazardous environment, the fire truck carrying a heavy rescue unit becomes more than a symbol of response—it becomes a moving workshop of specialized problem-solving. Heavy rescue is not merely a bigger or shinier truck; it is a carefully engineered capability designed to extend the reach of firefighters into situations that demand precision, restraint, and technical ingenuity. In many communities, these units are deployed for incidents where standard fire apparatus would struggle to stabilize the scene, access the victims, or remove them without causing further harm. The concept rests on a simple, critical idea: when time is measured in minutes and lives depend on controlled maneuvers, a dedicated set of tools, trained personnel, and a disciplined approach can tip the balance from peril to rescue. The chapter that follows does not celebrate equipment in isolation. It treats heavy rescue as a system—a coordinated blend of hardware, people, processes, and risk management that must be understood in the context of urban and rural realities, evolving threats, and the standards that guide safety and performance.

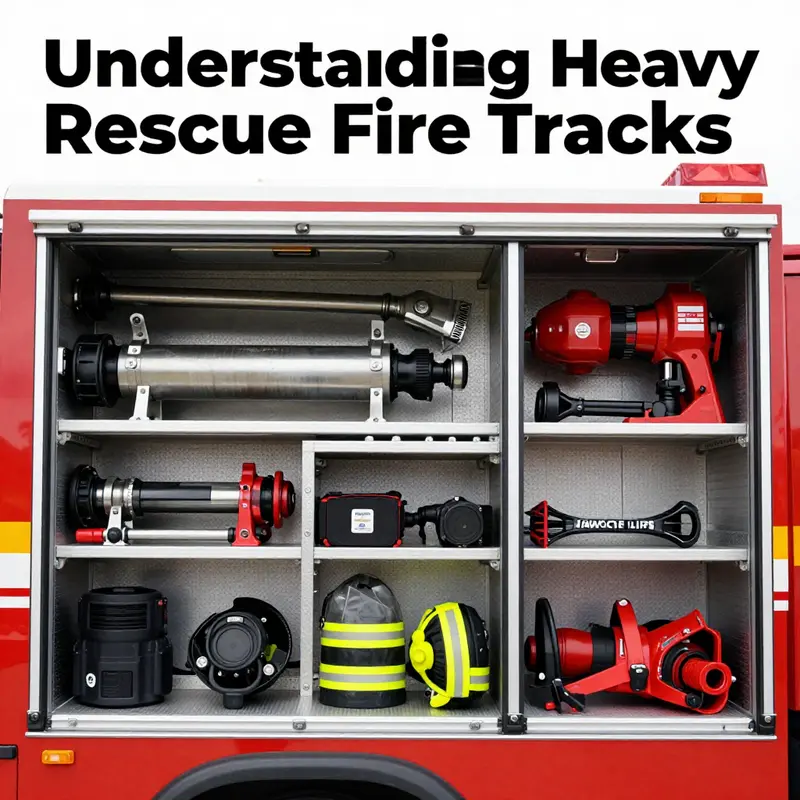

At the core of a heavy rescue unit are hydraulic rescue tools—powerful devices that can pry open, cut, spread, and lift in ways that human strength alone cannot. Rather than a single tool, the unit carries a toolbox of functionally distinct devices: hydraulic cutters capable of separating metal from metal, spreaders that pry and pry again to widen openings, and hydraulic rams that push with controlled force to create an escape route for a trapped person. These are complemented by heavy-duty airbags, which can lift vehicles or crush-prone debris with precision, reducing the risk of secondary injury as rescuers work to free the victim. Alongside the hydraulics sit cutting torches, power saws, and lighting systems that illuminate dark, unstable spaces so every motion can be calculated rather than improvised. Ventilation equipment helps manage smoke, toxic fumes, and heat, ensuring that occupancy remains within survivable limits and that responders can operate without compromising their own safety.

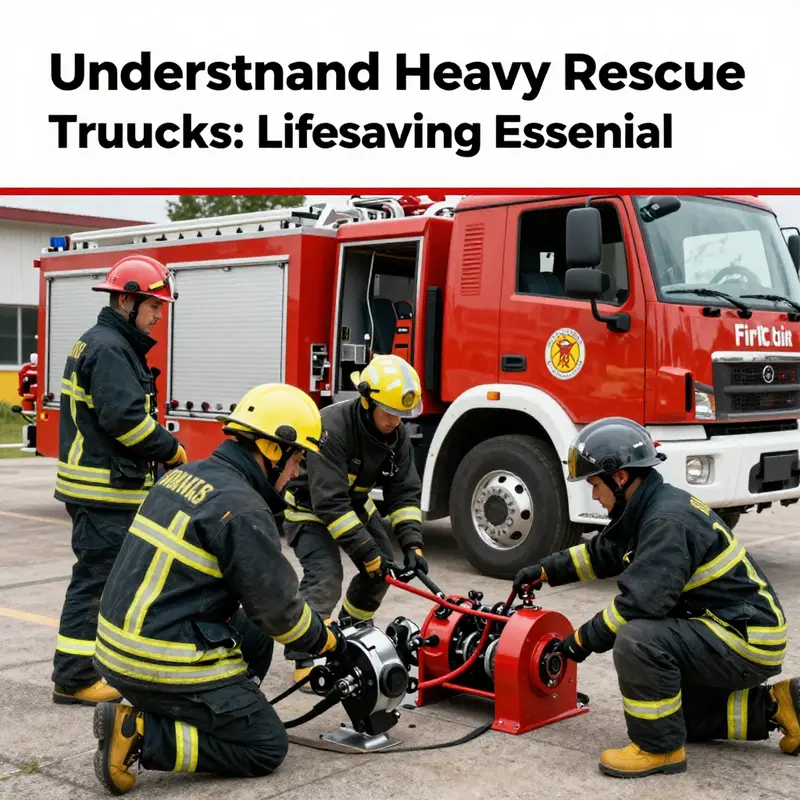

The equipment list might seem almost cinematic, but the reality is governed by careful design and relentless maintenance. Heavy rescue crews rely on more than tools; they rely on a philosophy of preparedness. A typical heavy rescue crew includes firefighters who are certified in technical rescue disciplines and who routinely train for the unpredictable textures of a scene—an unstable building, a vehicle resting on a compromised surface, or a trench that could shift without warning. On-board medical capabilities are common too, with paramedics or EMTs trained in tactical medicine ready to treat life-threatening injuries while preserving a delicate balance between rapid extraction and medical stabilization. The crew’s expertise is layered: beyond the mechanical know-how of using jacks and cutters, there is an understanding of how to read a scene, how to coordinate with other agencies, and how to pace the rescue so that every intervention remains under control. This combination of tools and talent makes heavy rescue units especially valuable in incidents where the objective is not only to reach a victim but to reach them safely, quickly, and with minimal additional risk.

The scenarios that demand heavy rescue are often complex by design. In urban settings, multi-vehicle crashes can quickly escalate into entrapment with airbags deployed, doors welded shut by the force of impact, and chassis and glass creating additional barriers to access. In structural collapses, the danger is not only the debris but the potential for secondary collapse—the weight of overhead structures shifting as a rescue progresses. Confined-space rescues require meticulous air management and the ability to maneuver through tight quarters without triggering a dangerous chain reaction in the environment. Trench rescues pose a different set of hazards, including shifting soil, water ingress, and limited visibility. In all these cases, the heavy rescue unit is expected to perform more than once—to establish hazard control, stabilize the scene, create an entry path, and deliver care to the injured, all while maintaining a safety-first discipline that protects both victims and responders. The tools enable a sequence: assess, access, free, extricate, and treat, each step tightly linked to the one that precedes it.

The operational tempo of a heavy rescue response depends on how well the unit integrates with the broader incident command structure. Scene safety and risk assessment are ongoing processes, not one-off checks. The presence of heavy rescue personnel often signals to the incident commander that a more thorough surgical approach is available, allowing the command post to allocate resources with more confidence. When a scene becomes unstable, the unit can execute controlled modifications to the environment: shoring up a compromised wall to prevent further collapse, placing stabilizing devices to protect a trapped occupant, or creating a vertical or horizontal path for extrication. Each maneuver is chosen not for speed alone, but for its capacity to reduce risk of secondary injury while maintaining momentum toward the victim. The decision to deploy heavy rescue is rarely about one heroic act; it is about coordinating a chain of deliberate actions that collectively maximize the chance of survival.

Training is the thread that binds equipment to outcomes. Heavy rescue squads engage in scenario-based drills that simulate the most demanding conditions: a car wedged under a bridge with unpredictable load transfer, a warehouse fire with a trapped worker behind a compromised wall, or a hillside trench where water ingress threatens both the victim and the responders. Drills emphasize not only the mechanical steps of operation but the softer, equally essential elements: communication with the victim, the cadence of ventilations and lighting, and the quiet, constant attention to structural indicators such as cracking sounds, unusual odors, or sudden shifts in debris patterns. The best teams rehearse under conditions that approximate the real world as closely as possible, with the same emphasis on safety protocols, radio discipline, and checklists that govern any high-stakes operation. The culture of readiness extends to gear upkeep, which includes routine inspections, calibration of hydraulic systems, and replacement of worn components before a failure can occur in a live rescue. In an era where technology advances at a brisk pace, the training loop—practice, critique, refine—remains the backbone of effective heavy rescue.

In addition to the obvious mechanical capabilities, heavy rescue units carry a broader set of assets that influence both strategy and outcome. Lighting systems illuminate a scene without adding heat or causing glare that could blind responders. Ventilation equipment removes smoke and hazardous gases, creating a healthier breathing zone for both victims and responders. Power sources, often portable generators, ensure that tools remain operational even when the incident stretches into the night or away from power infrastructure. Access and egress planning, meanwhile, grow from the team’s intimate knowledge of the local built environment, including typical construction practices, common failure modes, and the locations of utilities that could complicate a rescue. The crew’s medical presence ensures that a victim can be stabilized in the critical minutes after exposure to trauma, bridging the interval until definitive care arrives. The integration of medical care with mechanical access makes heavy rescue an early and continuous medical resource rather than a post-extraction afterthought.

Communities evaluate the value of heavy rescue through a practical lens: how often are the incidents that require such specialized intervention likely to occur, and what is the cost of under-resourcing versus over-resourcing? This calculus is seldom simple, because it depends on local factors such as traffic density, industrial activity, age and condition of buildings, and the presence of heavy machinery at work sites nearby. Urban centers with dense traffic and high-rise construction may rely on rapid extrication and high-capacity stabilization, while rural or industrial areas might encounter large vehicle accidents or structural collapses in settings where access is more challenging. In both contexts, the heavy rescue unit offers a critical multiplier: faster access to victims, better stabilization, and an organized, disciplined approach that reduces the potential for further harm. Departments often employ risk-based planning, using local incident data to align the fleet with the most likely scenarios. The aim is not to guarantee success in every incident but to maximize the probability that a trapped person can be freed quickly and safely while minimizing exposure to responders.

From a governance perspective, standards and specifications shape what a heavy rescue unit must be capable of delivering. The National Fire Protection Association’s standards for emergency services vehicle operations provide a frame for design, performance, and safety that helps ensure consistency across departments and jurisdictions. The emphasis on reliability, operator safety, and interoperable communications reminds agencies that heavy rescue is not a standalone gadget but a function within a larger safety system. These standards guide decisions about the layout of equipment compartments, the ease of tool access, and the ability to retrace steps if a sequence proves inadequate. They also remind us that the value of heavy rescue does not lie solely in winning a single moment of extraction. It lies in the resilience of the scene management, the discipline of the team, and the capacity to adjust tactics in response to evolving conditions. The result is a capability that can be deployed swiftly, used effectively, and maintained so that it remains ready for the next call.

In conversations about fleet design and regional needs, it is common to encounter discussions about customizing or scaling heavy rescue capabilities. Some departments explore options that maintain a core set of life-saving tools while allowing for modular additions to address local hazards. This approach recognizes that resource allocation should reflect risk exposure rather than abstract popularity. For discussions about responsible resource planning and adaptable solutions, consider looking into resources that explore comprehensive approaches to developing-country contexts, including models that emphasize durability, versatility, and cost-effectiveness. For a deeper look at one route some departments are pursuing, see the discussion on comprehensive-fire-trucks-for-developing-countries-advanced-solutions-for-diverse-firefighting-needs. Here, the emphasis is on delivering robust, flexible response options without sacrificing core safety standards, a philosophy that parallels the priorities of heavy rescue teams working in more resource-constrained environments. That linkage underscores a broader truth: heavy rescue is as much about thoughtful design and disciplined deployment as it is about raw power or an impressive toolbox. When communities invest in both the people and the procedures that keep these tools effective, the return on investment is measured not only in saved lives but in safer, more predictable responses that reduce the risks faced by responders themselves.

The interplay between equipment, training, and standards inevitably leads to a practical question about accountability and public safety. Departments must balance the value of a heavy rescue unit against the realities of budget, call volume, and maintenance demands. A heavy rescue rig is expensive to purchase and costly to operate, but its impact on life safety can be substantial in the right circumstances. The decision to purchase, upgrade, or retire a heavy rescue capability should be grounded in objective analysis of local data, including the frequency and severity of incidents that demand technical rescue. It also requires ongoing collaboration with other agencies—law enforcement, EMS, urban search-and-rescue teams, and utilities—to ensure that the response remains coherent when multiple disciplines converge on a complex scene. In this sense, heavy rescue becomes part of a broader culture of readiness where departments continuously assess risk, refine tactics, and invest in people as much as in tools. The end goal is clear: to shorten the distance between alert and intervention, and to do so in a manner that preserves life and minimizes harm to those who respond.

External resources illuminate the framed approach that underpins these capabilities. The NFPA standards for vehicle operations shape the expectations around how a heavy rescue unit should be designed and how crews should operate within and around the vehicle. For practitioners and policymakers alike, engaging with these guidelines helps translate a high-stakes capability into consistent, measurable performance. The standards act as a common language across jurisdictions, enabling better training, safer operations, and more effective collaboration during interagency missions. As communities continue to confront evolving risks—from aging infrastructure to new transport patterns—the core promise of heavy rescue remains: a committed, highly skilled team equipped with the right tools and a deliberate plan, ready to turn a scene of danger into a scene of rescue.

External resource: https://www.nfpa.org/codes-and-standards/databases/nfpa-1917

The Heart of Heavy Rescue: Essential Tools, Reach, and the Science of Saving Lives on the Fire Truck

A heavy rescue fire truck embodies a philosophy as much as a collection of equipment. It is a mobile workshop, a precision platform, and a lifeline all rolled into a single, heavily armored chassis. While every fire service unit carries gear to combat flames, heavy rescue is trained to confront scenarios where victims are trapped behind deformed metal, beneath rubble, or inside compromised structures. In these moments, success hinges on a coordinated orchestration of tools, technique, and timing. The equipment found on a heavy rescue unit is not a random assortment of gadgets; it is a carefully chosen, interoperable suite designed to transform a scene from chaos into a controlled environment where rescuers can distance themselves from danger while guiding victims to safety. In practice, the power of heavy rescue lies less in flash and speed and more in the ability to adapt to the geometry of a scene, to stabilize hazards, and to create the necessary space for people to be released with as little harm as possible. The core philosophy is straightforward: bring the right tool to bear at the right moment, and the path to extraction becomes clearer, even when the surroundings are inconsistent or unstable.

At the heart of the heavy rescue apparatus is a system of interlocking capabilities. The front end of the vehicle often features a heavy-duty winch with a substantial pulling capacity. This winch can recover vehicles buried in mud or ditches, reposition wreckage that blocks egress routes, or anchor the scene during complex lifting operations. The winch’s strength is not a mere statistic; it is a practical lifeline during a critical window when every centimeter of movement counts. When a vehicle is stuck, a controlled pull can create the space needed for responders to begin cutting or spreading operations. The force delivered by the winch must be managed with restraint and precision, and that precision is what protects patients and bystanders alike while the rescue unfolds.

Mid-vehicle, a heavy rescue truck houses a robust crane—a mechanical arm capable of lifting heavy loads and reaching into parts of a wreck or collapse where human access is impractical or impossible. A crane with several tons of lift capacity and a substantial reach becomes a tactical multiplier. It enables responders to maneuver large debris, reposition compromised structural members, or lift heavy components that could otherwise trap a person further. The reach is not merely about extension; it is about control and positioning. Every degree of movement is deliberate, as even small miscalculations can create new hazards or fail to free a trapped victim. The crane’s versatility is further enhanced by a secondary lifting tool in the same vicinity—an onboard forklift. While not every department relies on a forklift in rescue scenarios, when a job requires moving heavy, awkward loads without causing additional injuries to victims, the forklift becomes a silent workhorse. In practice, it allows responders to relocate large metal fragments, supports, or salvage items with steadiness and speed, reducing the need for manual manipulation in hazardous environments.

The hydraulic rescue tools carried in the equipment compartments form the core of extrication capability. Hydraulic cutters or shears are designed to slice through deformed metal, even when it has crumpled under the force of a crash or collapse. These tools cut and contort with power, producing clean openings that permit access to trapped occupants. Paired with spreading tools, they create space to reach victims and to perform necessary medical interventions without aggressive, counterproductive forcing that could aggravate injuries. The sheer variety of hydraulic components is not about spectacle but about adaptability. Some tasks require a precise cut to preserve structural integrity, while others demand a broad mouth to pry apart joined metal. The hybrid function of cutting and spreading is what enables responders to transition from stabilization to access, and from access to extraction, in a smoothly coordinated fashion.

In addition to cutting and spreading, high-capacity airbags play a decisive role in creating safe space around a trapped person. These air cushions can lift, separate, or stabilize sections of metal and debris, distributing pressure over larger areas to prevent further injury. The ability to generate a controlled gap between obstructing material and the patient makes possible the careful insertion of medical devices or immobilization devices. The airbags, when deployed in a calculated sequence, turn a narrow opportunity into a safe corridor for removal. The use of airbags also features in stair- and slope-rescue operations where materials shift under load. Properly designed, these systems reduce the risk of secondary collapse and provide responders with the confidence to proceed with delicate extrication steps.

The rescue toolbox extends beyond the immediate objective of freeing a victim. A hidden or integrated fire suppression system may be included on some heavy rescue configurations. For rapid response in the event of a flare-up during a hazardous operation, a foam-water mix stored in a sizable tank and driven by a pneumatic pump can suppress flames without compromising the rescue. In scenes where a fuel leak ignites or where hot surfaces threaten a trapped patient, this capability provides a rapid, localized defense. It is not about replacing a dedicated suppression unit but providing an emergency adjunct that preserves the safety margin on a scene where there are competing hazards. Such features underscore the layered thinking behind heavy rescue design: equipment is chosen not only for its primary rescue function but also for how it can help manage secondary threats that arc, fuel, or radiant heat might pose in the same moment.

A more recent evolution in heavy rescue is the integration of remote operation capabilities. State-of-the-art models offer remote control options and even virtual reality interfaces that enable operators to perform tasks from a distance, sometimes up to two kilometers away. This is a tactical adaptation born from an understanding that the safest way to perform certain operations is to remove the operator from immediate danger while still maintaining precise control over equipment. Remote operation translates to improved safety for responders and increased precision in the execution of delicate steps. It also enables teams to conduct collaborative, multi-position tasks—one team stabilizes and monitors the environment, while another manages tools from a safer vantage. The shift toward remote operation demonstrates how the heavy rescue toolbox has grown from a purely mechanical collection of devices into a digitally empowered, coordinated system. It is a reminder that the modern fire truck is as much a platform for information and control as it is for raw force.

All of these components—winches, cranes, forklifts, hydraulic cutters and spreaders, airbags, foam suppression, and remote operation—are interdependent. The real power of heavy rescue emerges when responders deploy these tools in concert, guided by a shared plan and the disciplined rhythms of a well-rehearsed team. The sequence matters. First, responders stabilize the scene to prevent further harm. Then they establish a path to access, using cutting and spreading tools to create safe corridors. They use airbags to control the space and to minimize movement of the patient during extraction. When the environment allows, the crane and the forklift move large pieces or load materials away from the patient to clear space for medical personnel. Throughout, a curtain of protection—foremost from the responders’ own training, and secondarily from the vehicle-mounted suppression system if needed—helps ensure that the patient experiences the least amount of additional trauma during the process.

The training and readiness that undergird heavy rescue are as crucial as the hardware. A crew must be proficient in coordinating mechanical operations with patient care. They must understand the geometry of every tool, know the limits of reach and lift, and anticipate how deformations or shifts in the scene will alter the sequence of actions. Drills routinely simulate vehicle extrications, structural gaps, and entrapments under varying lighting conditions, weather, and stability scenarios. The goal is a reproducible, scalable response where every member knows their role and can adapt to evolving conditions without hesitation. The importance of teamwork cannot be overstated. In a rescue that unfolds under pressure, miscommunication or hesitation can turn a known risk into a life-threatening event. A heavy rescue unit thus functions as a mobilized, on-call rescue station that can be deployed quickly but with the purposeful, methodical cadence of a surgical team.

The equipment is also a reminder of the realities of budget, geography, and mission scope. Heavy rescue trucks are designed to be resilient and adaptable, capable of serving in urban centers and rural zones alike. They often travel long distances, through rough roads and challenging terrain, to reach incidents. As a result, their design emphasizes durability, reliability, and ease of maintenance. The tools must be robust enough to operate in harsh environments, easy enough to repair with available parts, and versatile enough to handle a wide range of scenarios. This adaptability is precisely what makes heavy rescue units central to modern emergency response. Their capability is not defined by a single heroic maneuver but by the ability to sustain a complex, multi-step rescue in the face of uncertainty.

In thinking about the broader implications, there is a strong argument for viewing heavy rescue as a platform for scalable emergency response. In many contexts, including developing regions with diverse needs, the same core concept applies: a vehicle that carries a core set of resilient, interoperable tools can be configured to meet local realities. A truck can be equipped with a different balance of lifting, cutting, and stabilization tools to suit local vehicles, building styles, and typical accident patterns. The emphasis remains on training, maintenance, and the ability to integrate with a wider incident command structure. For departments pursuing modernization, there is value in approaches that prioritize modularity, cross-training, and predictable performance over a single, bespoke system that might become obsolete or mismatched to future needs. To illustrate how these ideas are being implemented globally, one approach focuses on comprehensive, customizable fire trucks designed for diverse rescue needs while remaining reliable, cost-effective, and responsive—an approach that aligns with practical constraints and the realities of service delivery in varied environments. comprehensive customized fire trucks for developing countries—reliable, cost-effective, and responsive solutions.

The practical outcomes of heavy rescue are measured not just in lives saved, but in the confidence that responders gain when they walk onto a scene. The equipment becomes a language—the ability to ask for and receive exactly what is needed to clear a path, stabilize a risk, and reach a patient. When a child is trapped in a collapsed vehicle or a worker is pinned beneath a fallen beam, the rescue crew speaks this language with practiced clarity: stabilize, access, extricate, and treat. Each tool becomes a word in that language—a word that, when spoken in the right order and with the right timing, joins with medical care to deliver a hopeful outcome. In this sense, heavy rescue is less about the spectacle of heavy machinery and more about the disciplined choreography of an emergency response, where every kilogram of force, every centimeter of reach, and every second saved can influence the arc of a rescue from danger to relief.

As standards evolve, the journey of heavy rescue continues to be shaped by both field realities and analytic oversight. The development of equipment, training, and best practice is a dialog among responders, manufacturers, and safety regulators. The goal is to keep pace with new hazards—whether they arise from increasingly complex vehicle designs, higher-energy crashes, or unpredictable collapse scenarios—while preserving the human-centered focus that defines emergency response. In this evolving landscape, heavy rescue equipment remains a tangible bridge between technical capability and compassionate service. It embodies the commitment to approach the most daunting scenes with a toolkit that is not only powerful but also adaptable, disciplined, and relentlessly focused on safeguarding life.

For readers seeking a formal orientation to how these standards and capabilities are codified, a leading reference outlines the equipment standards and the evolving expectations for heavy rescue operations. The external resource provides a foundation for understanding the safety, training, and design principles that guide modern heavy rescue work.

External reference: https://www.nfpa.org/News-and-Research/News/2026/January/Heavy-rescue-fire-truck-equipment-standards

Forging Readiness on the Heavy Rescue Frontline: Training and Qualifications Make the Fire Truck a Precision Tool

Heavy rescue operations rely not just on powerful tools but on a disciplined system of training and qualification. This program translates a specialized vehicle into a reliable, adaptable platform capable of complex tasks under pressure. Rescuers learn to read scenes, assess risk, and coordinate multiple actions while maintaining safety for victims and teammates.

The training framework is built on national standards and phased curricula that move learners from foundational rope systems to high-angle rescue, stabilization, and breaching techniques. Instructors emphasize safety, leadership, and decision-making as core competencies, ensuring that every action on the fire truck is purposeful and coordinated rather than improvised.

Certification marks the culmination of demonstrated proficiency, but real readiness depends on ongoing refreshers, drills, and after-action reviews. A robust ecosystem supports continuous improvement and adapts to evolving risks and technologies while keeping the focus on life-safety outcomes.

Heavy Rescue on the Frontline: How Specialized Apparatus Redefines Emergency Response

Heavy rescue on the fire ground involves more than a larger truck and more hoses. It is a deliberately equipped platform designed for complex scenes where victims are trapped, structures are unstable, and time matters. Heavy rescue units carry hydraulic tools, cutters, spreaders, stabilization gear, and sometimes lifting systems. They also hold ventilation equipment, lighting, and sometimes tools for vehicle extrication such as struts and cribbing. The aim is to reach, stabilize, access, and extract under conditions that would overwhelm standard engines. Because these missions unfold in demanding environments, heavy rescue units require a blend of advanced equipment, rigorous training, and strong coordination among crews. This coordination makes complicated operations appear orderly on the ground.

The gear on a heavy rescue unit is chosen for a single purpose: to convert entrapment scenarios into solvable mechanical problems. The hydraulic tools, powered by high-capacity pumps, act as primary instruments for prying, cutting, and spreading. Stabilization devices such as cribbing and struts prevent further movement of vehicles, debris, or collapsing structures. This is essential because any misstep can turn a rescue into a recovery. Beyond raw power, skilled operators use control techniques that minimize additional harm while maximizing access. The tools are about precision—where to apply force, how much, and for how long before relief moves to the next phase.

The crews who run heavy rescue are specialists, often drawn from urban search-and-rescue teams and technical rescue squads. Their work blends firefighting fundamentals with an engineering mindset. They interpret architectural cues, anticipate hidden voids, and conduct lift plans in real time. This is a dynamic choreography: as a scene evolves, the crew updates their plan, assigns roles, and coordinates with EMS, police, and public works. The result is a response that feels deliberate and life-saving in critical moments. The need for synchronization becomes evident in large incidents where multiple agencies converge. Heavy rescue anchors a broader response architecture that must function under stress and time pressure.

This integration matters because heavy rescue does more than free a trapped person. It stabilizes the scene to reduce the risk of further harm. Vehicle extrication is not only about removing a victim; it is about removing hazards, shifting loads safely, and creating a corridor for medical care. In structural collapses, stabilization means the difference between a controlled operation and a dangerous failure. Ventilation controls the atmosphere inside a compromised space, and lighting extends the window of opportunity for precise cuts. All of these elements—tools, stabilization, ventilation, and lighting—cohere into a capability that makes a precarious scene manageable with a defined plan and measurable outcomes.

The impact of heavy rescue on speed and scope is not merely about expanding capabilities. It reshapes decision-making at the scene. In the earliest minutes of a major incident, dispatch must balance urgency with the risk of premature actions. The crew performs a rapid triage of risk zones, potential entrapment, hazards, and victim proximity. This appraisal becomes a tactical plan that can be adjusted as conditions evolve. A well-prepared unit can establish a safe zone, position stabilizers, and begin controlled cuts while EMS stabilizes a patient and police secure the perimeter. This synergy makes heavy rescue an accelerant for life-saving outcomes rather than a mere fleet addition.

The kinds of incidents that demand heavy rescue are diverse: major motor vehicle crashes with multiple trapped occupants, industrial accidents with heavy machinery or dense debris, and structural collapses after fires or natural events. In flood scenarios, teams coordinate search-and-rescue with evacuee transfer and on-scene relief, requiring flood-water rescue capability, rapid transport, and patient-care continuity. The literature points toward adaptable fleet configurations as a practical approach for regions with varying hazard profiles and budgets. Flexible, scalable fleets that can be reconfigured for different scenarios, from vehicle extrication to urban search-and-rescue, offer resilience. Developing-country contexts are often discussed in terms of comprehensive, customizable fire trucks designed to meet diverse rescue needs.

Beyond hardware, planning is central. A well-conceived plan starts with an understanding of the urban fabric and risks that shape vulnerability. It maps response zones, choke points in transportation, and anticipated heavy rescue needs. It also accounts for secondary hazards such as gas leaks or hazardous materials exposure. A robust plan includes public communication strategies to manage crowds and direct evacuees, reducing the risk of additional injuries during evolving incidents. Heavy rescue is as much about anticipation as reaction, driven by data-informed risk assessment, resource allocation planning, and readiness that allows action the moment a call comes in.

There is a broader social dimension: when rescuers are deployed to flood zones, collapsed structures, or industrial sites, the goal is to save lives and to consider the communities those lives belong to. Integrated metrics that weigh social vulnerability push responders to consider where people live, how accessible help is, and what barriers exist to timely rescue. This mindset shapes who gets help first and how resources are distributed as the scene evolves. The emerging consensus is that modern heavy rescue must balance speed with equity, efficiency with safety, and technical prowess with public trust. The result is a humane form of emergency response that treats rescue work as a continuum from early warning and rapid response to stabilization, extraction, and recovery.

In reflecting on the practicalities of heavy rescue, it is worth acknowledging limits and ongoing improvement. Equipment can be upgraded, drills refined, and interagency protocols tightened, but the core challenge remains: how to intervene decisively when time is scarce and conditions are volatile. The best programs invest in training that blends technical proficiency with scene management, risk assessment, and survivor care. They also invest in logistics to keep teams supplied with consumables, spare parts, and maintenance schedules so a unit can respond again within hours rather than days. As cities confront climate risks, aging infrastructure, and evolving hazards, the relevance of heavy rescue only grows. It is engineering applied to human life, turning heavy tools into careful, deliberate actions, and the science of executing a plan that saves lives while protecting those who come to help.

Final thoughts

The significance of heavy rescue fire trucks cannot be overstated. They serve as lifelines during dire emergencies, equipped with the most advanced tools and staffed by specially trained personnel. Understanding the role, equipment, training, and impact of heavy rescue operations enhances community awareness and appreciation for these first responders. These units are crucial for ensuring safety and providing effective emergency response, making training and awareness essential for community resilience.